3D MODELING

Women Graduates are trained with basics in Industry application from basic science Mathematics, Physics, Chemistry

Training in application Software by Industry Professional, to train others with preparation as TRAINER to empower.

Empowering areas are ACADEMIC SERVICE-ENTREPRENEURSHIP-DESIGN SERVICE-INDUSTRIES-SOCIAL ENGINEERING

Why enterprises and users choose KOMPAS-3D:

Availability of required functionality

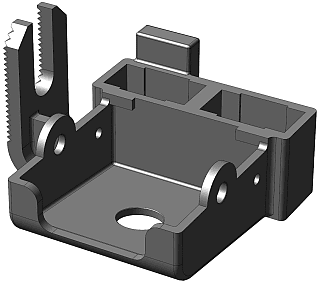

- Designing products of any complexity

- High-quality execution of documentation for ESKD or SPDS

- Automation of industry tasks

- Ease of learning

- Free technical support

- Flexible licensing policy

- Preferential substitution of foreign CAD systems

- Embedding in the enterprise PLM environment

KOMPAS-3D

3D modeling system

KOMPAS-3D

3D modeling system

KOMPAS-3D is a Russian 3D design system that has become the standard for thousands of enterprises and hundreds of thousands of professional users.

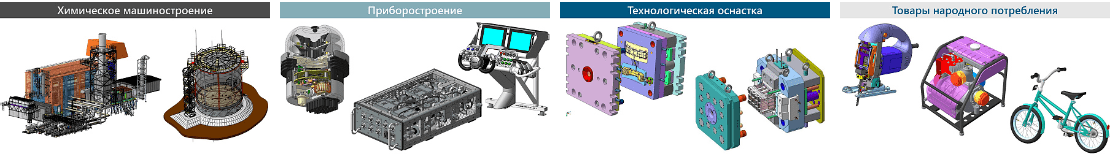

KOMPAS-3D is widely used for designing products of the main and auxiliary industries in such industries as mechanical engineering (transport, agricultural, energy, oil and gas, chemical, etc.), instrument making, aircraft building, shipbuilding, machine tool building, car building, metallurgy, industrial and civil engineering, consumer goods, etc.

- Companion-Integrator

- POLYNOMIAL:MDM

- ESPRIT

- PILOTMAN:PLM

- QiBox

- ESKD classifier

- Directory Materials and Assortments

- ADEM

- KompasFlow

- APM FEM

- Reference Standard Products: 2D and 3D Fasteners

- Directory of Standard Products: Parts, assemblies and structural elements 2D and 3D

- Directory of Standard Products: Electrical Apparatus and Fittings 3D

- Handbook Standard Products: Model Designer

- Directory Standard Products

- Materials and Assortments: server

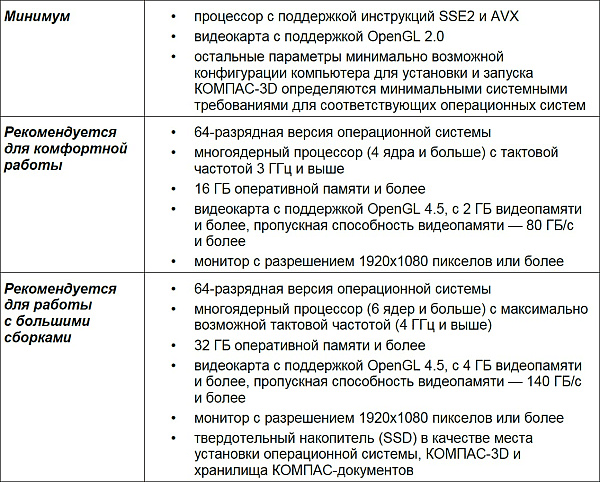

System requirements: - Windows 10;

- Windows 8.1;

- Windows 7 SP1 and above.

Both 32-bit and 64-bit versions of operating systems are supported.

Contains:

- Windows 10;

- Windows 8.1;

- Windows 7 SP1 and above.

Both 32-bit and 64-bit versions of operating systems are supported.

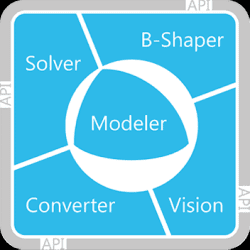

COMPLETELY IMPORT-INDEPENDENT SYSTEM

KOMPAS-3D is based on the Russian geometric core C3D (created by C3D Labs, a subsidiary of ASCON) and proprietary software technologies.

COMPLETELY IMPORT-INDEPENDENT SYSTEM

KOMPAS-3D is based on the Russian geometric core C3D (created by C3D Labs, a subsidiary of ASCON) and proprietary software technologies.

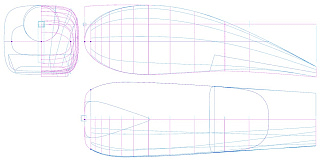

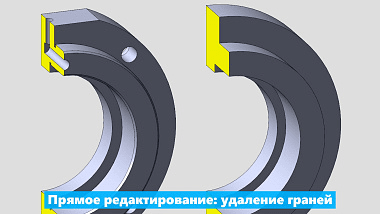

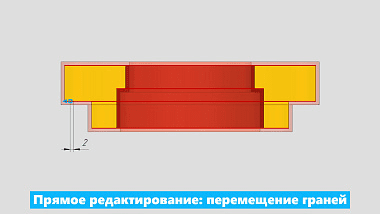

KOMPAS-3D supports the following types of modeling:

- solid state

superficial

sheet

object

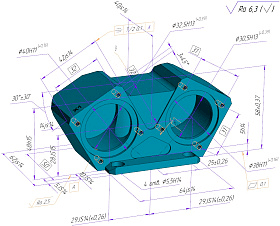

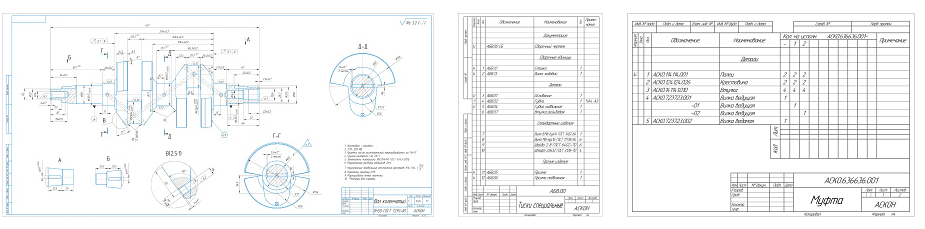

SUPPORT OF GOST 2.052-2015 "ELECTRONIC PRODUCT MODEL"

KOMPAS-3D contains tools for creating necessary and sufficient data in a 3D model for its production: dimensions, designation elements (axial lines, threads, bases, shape tolerances, etc.), technical requirements, unspecified roughness. This means that KOMPAS-3D already now allows you to abandon the electronic drawings of the product.

SUPPORT OF GOST 2.052-2015 "ELECTRONIC PRODUCT MODEL"

KOMPAS-3D contains tools for creating necessary and sufficient data in a 3D model for its production: dimensions, designation elements (axial lines, threads, bases, shape tolerances, etc.), technical requirements, unspecified roughness. This means that KOMPAS-3D already now allows you to abandon the electronic drawings of the product.

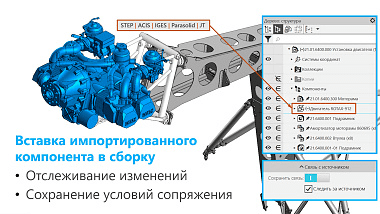

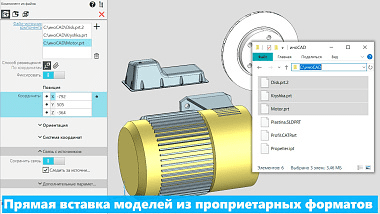

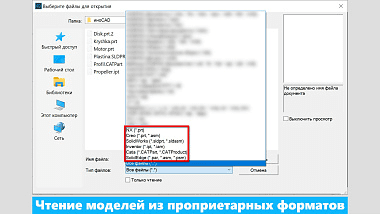

DATA EXCHANGE WITH OTHER CAD SYSTEMS

Possibilities of KOMPAS-3D to exchange information with other CAD systems:

- export and import (with subsequent editing) of 3D geometry and model data via STEP, ACIS, IGES, Parasolid, etc. formats;

- export and import (with subsequent editing) of 2D geometry via DWG and DXF formats;

- direct import (with subsequent editing) of files of the most common CAD systems (SolidWorks, Autodesk Inventor, Solid Edge, Creo, NX, Catia).

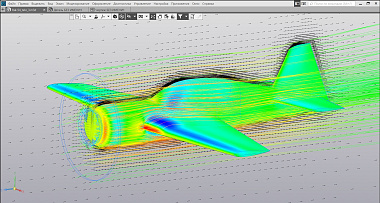

CALCULATIONS AND ANALYSIS

KOMPAS-3D allows you to perform the following engineering calculations:

- calculation of mass-centering characteristics (2D/3D)

- calculation of springs and mechanical gears (2D/3D)

- dynamic analysis of the behavior of mechanisms (3D)

- express strength analysis (3D)

- topological product optimization (3D)

- geometric optimization (3D)

- liquid and gas flow analysis (3D)

- thermal conductivity and natural convection analysis (3D)

- calculation of dimensional chains (2D)

CALCULATIONS AND ANALYSIS

KOMPAS-3D allows you to perform the following engineering calculations:

- calculation of mass-centering characteristics (2D/3D)

- calculation of springs and mechanical gears (2D/3D)

- dynamic analysis of the behavior of mechanisms (3D)

- express strength analysis (3D)

- topological product optimization (3D)

- geometric optimization (3D)

- liquid and gas flow analysis (3D)

- thermal conductivity and natural convection analysis (3D)

- calculation of dimensional chains (2D)

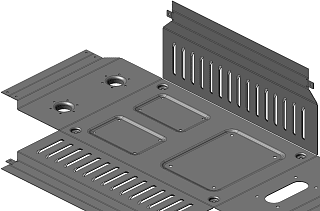

HIGH-QUALITY EXECUTION OF DESIGN AND PROJECT DOCUMENTATION

One of the main advantages of KOMPAS-3D is the preparation of documentation in full compliance with the rules of ESKD or SPDS. This is confirmed by users of other CAD systems by making 3D models of products in their CAD, and drawings, specifications, diagrams, sheets - in KOMPAS-3D.

HIGH-QUALITY EXECUTION OF DESIGN AND PROJECT DOCUMENTATION

One of the main advantages of KOMPAS-3D is the preparation of documentation in full compliance with the rules of ESKD or SPDS. This is confirmed by users of other CAD systems by making 3D models of products in their CAD, and drawings, specifications, diagrams, sheets - in KOMPAS-3D.

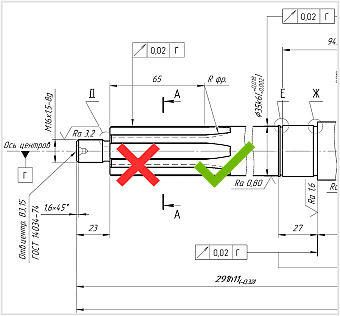

FINDING AND FIXING ERRORS IN DRAWINGS AND 3D MODELS

KOMPAS-3D allows you to check documents for compliance with ESKD design standards (for example, text placement or allowable distance between dimension lines), as well as check models for manufacturability (for example, the location of holes or allowed roughness values).

In total, about 200 different checks are available, which will improve the quality of the developed models and documentation and help to correct errors before the product is transferred to production.

FINDING AND FIXING ERRORS IN DRAWINGS AND 3D MODELS

KOMPAS-3D allows you to check documents for compliance with ESKD design standards (for example, text placement or allowable distance between dimension lines), as well as check models for manufacturability (for example, the location of holes or allowed roughness values).

In total, about 200 different checks are available, which will improve the quality of the developed models and documentation and help to correct errors before the product is transferred to production.

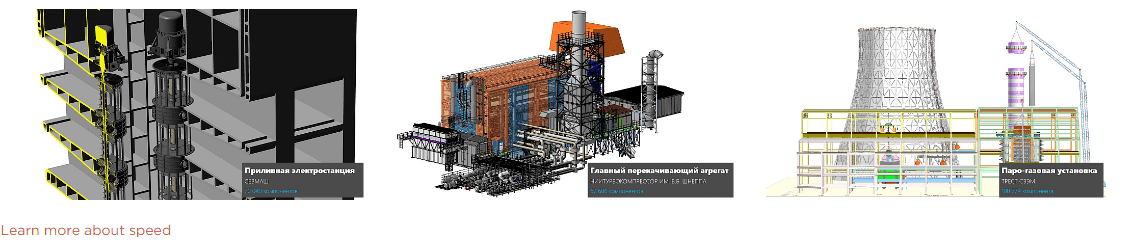

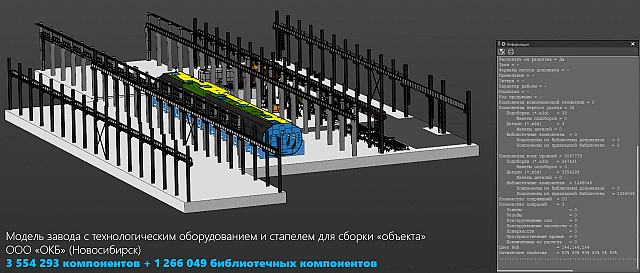

WORKING WITH LARGE ASSEMBLIES

It became possible to create products of any complexity thanks to the KOMPAS-3D speed concept implemented in 2018. However, work on system performance continues to this day, so each new version will be faster than the previous one. At the moment, about 40 processes have been accelerated, special methods for working with large assemblies have been introduced, and the necessary hardware resources (processors, video cards) are being used.

WORKING WITH LARGE ASSEMBLIES

It became possible to create products of any complexity thanks to the KOMPAS-3D speed concept implemented in 2018. However, work on system performance continues to this day, so each new version will be faster than the previous one. At the moment, about 40 processes have been accelerated, special methods for working with large assemblies have been introduced, and the necessary hardware resources (processors, video cards) are being used.

HARDWARE REQUIREMENTS:

HARDWARE REQUIREMENTS:

The use of MNP ensures the parallel development of product components by several performers, and also significantly reduces the time for making changes to the project by managing the product layout.

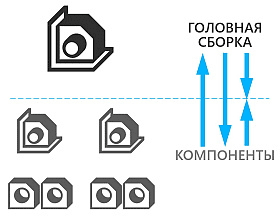

DESIGN METHODS

KOMPAS-3D supports several product design methods. The most promising in terms of speed is the top-down design technique (TOP or “top-down”). It consists of designing from the head assembly level down to the detail level.

DESIGN METHODS

KOMPAS-3D supports several product design methods. The most promising in terms of speed is the top-down design technique (TOP or “top-down”). It consists of designing from the head assembly level down to the detail level.

INTEGRATION WITH PRODUCT LIFECYCLE MANAGEMENT SYSTEMS

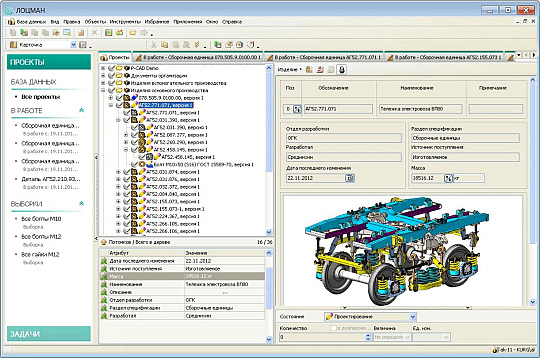

After the design is completed, the life cycle of a product (LCI) continues with the stages of technological preparation for production, testing, manufacturing, operation of the product, etc. To automate these stages, a control system of the LCI, a PLM-class system, is required. KOMPAS-3D contains the necessary tools for embedding (integration) into any existing PLM environments. The closest integration is organized with the engineering data management system LOTSMAN:PLM (developed by ASCON).

INTEGRATION WITH PRODUCT LIFECYCLE MANAGEMENT SYSTEMS

After the design is completed, the life cycle of a product (LCI) continues with the stages of technological preparation for production, testing, manufacturing, operation of the product, etc. To automate these stages, a control system of the LCI, a PLM-class system, is required. KOMPAS-3D contains the necessary tools for embedding (integration) into any existing PLM environments. The closest integration is organized with the engineering data management system LOTSMAN:PLM (developed by ASCON).

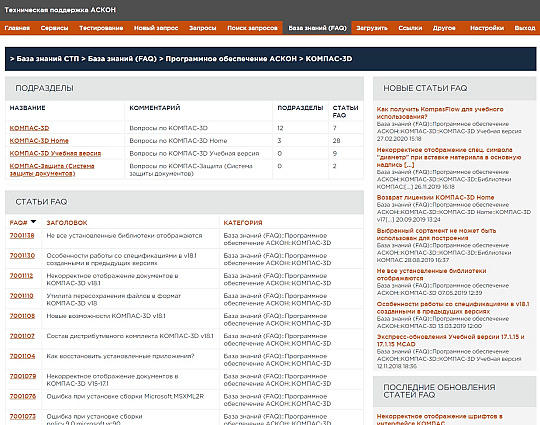

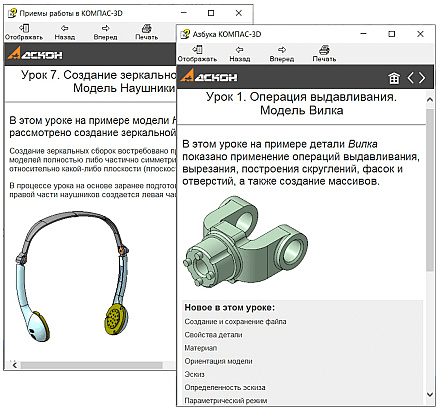

Are you just starting to master KOMPAS-3D? Complete a basic training course at the ASCON offices. For self-study, use the interactive 2D and 3D ABCs, work methods, help system, tips in the process of commands.

In recent years, the developers of KOMPAS-3D have accelerated the pace of product development - now within one version 3 times more new products are being implemented than before. Within five years, about 400 new products appeared, most of which were developed based on user suggestions.

The development of proposals and any incidents on the product is carried out by the ASCON Technical Support Service. Technical support for all licensed users of KOMPAS-3D is provided free of charge through the Personal Account of the technical support website .